About Us

Smart Engineering is an Organisation with a focus on strategy, research, and technology execution with in the Semiconductor and Automobile Industry.

Our blended industry focus on PCBA tooling’s uniquely enables us to develop and apply the most effective strategies, tactics, and technologies on behalf of emerging and leading brands looking forward to engage key customers to achieve exceptional and sustained business successes.

We continue to invest our time and Funds in Improving the manufacturing sector of PCBA tooling, Tool & Die Design, and Special Purpose machines. Smart Engineering provides solutions to the best and most innovative companies in the industries we serve. Our goal is to assist them in overcoming their challenges by offering the most innovative solutions possible, designed and fabricated with the highest technological tools and processes available.

Smart Engg is promised to provide customers with, yet simple solutions to their most complex problems. We will measure customer satisfaction based on our ability to exceed expectations and enable our customers to achieve faster product development and order fulfilment cycles.

Smart Engineering was Founded by two Professionals on April 2016 Having background of Design and Manufacturing experience more than a decade

Delivering products on time and efficiently is not always easy, but if done properly, it can help a business stand out from the competition.

PCB testing and conformal coating are critical processes in the manufacturing of electronic products. Accurate and reliable testing and coating can help ensure the functionality and longevity of electronic products. In this article, we'll discuss the importance of PCB testing and conformal coating fixtures and how Smart Engineering's offerings can help improve your manufacturing process.

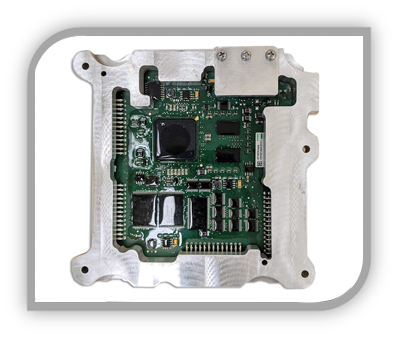

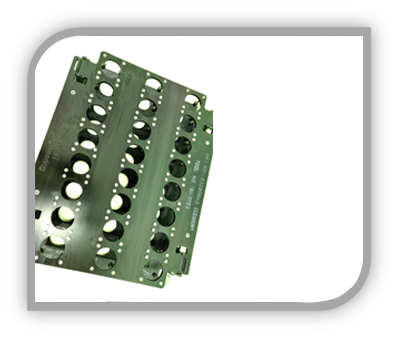

PCB testing fixtures are designed to hold the PCB in place during the testing process, ensuring accurate and consistent testing. They are designed to fit the dimensions and layout of the PCB being tested, ensuring that the testing process is accurate and consistent.

Smart Engineering offers a range of PCB testing fixtures designed to meet the needs of a variety of applications. Their offerings include custom fixtures, bed-of-nails fixtures, and flying probe fixtures. These fixtures are made from high-quality materials that can withstand the stresses of the testing process and are designed to be easily cleaned and reused.

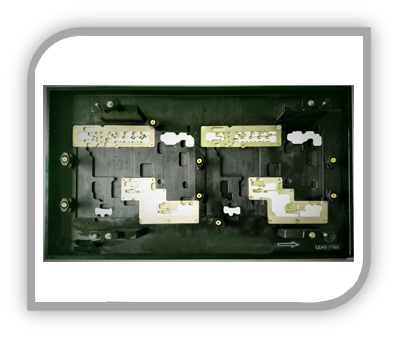

Custom fixtures are designed to fit the dimensions and layout of the PCB being tested, ensuring accurate and consistent testing. Bed-of-nails fixtures use a series of spring-loaded pins to make contact with the test points on the PCB, while flying probe fixtures use a set of movable probes to make contact with the test points. Conformal coating fixtures are designed to hold the PCB in place during the conformal coating process, ensuring accurate and consistent coating. They are designed to fit the dimensions and layout of the PCB being coated, ensuring that the coating process is accurate and consistent.Smart Engineering offers a range of conformal coating fixtures designed to meet the needs of a variety of applications. Their offerings include custom fixtures, spray coating fixtures, and dip coating fixtures. These fixtures are made from high-quality materials that can withstand the stresses of the conformal coating process and are designed to be easily cleaned and reused.

Custom fixtures are designed to fit the dimensions and layout of the PCB being coated, ensuring accurate and consistent coating. Spray coating fixtures are designed to hold the PCB and components in place while the conformal coating material is sprayed onto the surface. Dip coating fixtures are designed to hold the PCB and components in place while they are dipped into the conformal coating material.

Smart Engineering's PCB testing and conformal coating fixtures are customizable, allowing them to be tailored to the specific needs of each PCB being tested or coated. This customization ensures that the fixtures fit the dimensions and layout of the PCB precisely, which helps to ensure accurate and reliable testing and coating.

In addition to their testing and conformal coating fixtures, Smart Engineering also offers a range of other PCB assembly solutions, including router fixtures and soldering pallets. Their focus on quality, customization, and customer service makes them a trusted partner for manufacturers looking to optimize their manufacturing processes.

In conclusion, PCB testing and conformal coating fixtures are essential tools for any manufacturer using the PCB assembly process to manufacture electronic products. Smart Engineering's fixtures offer a range of benefits, including improved accuracy, consistency, and customization, which can help to optimize the manufacturing process and improve the overall quality of the finished product. If you are looking to optimize your PCB testing and conformal coating processes, consider working with Smart Engineering to develop a customized solution that meets your specific needs.

Semiconductor

Semiconductor Aviation

Aviation Medical

Medical Automobile

Automobile Special Purpose Machines

Special Purpose Machines 3 Axis Machining

3 Axis Machining 5 Axis Machining

5 Axis Machining Conventional Lathe with DRO

Conventional Lathe with DRO CNC Lathe Machining

CNC Lathe Machining High – Precision cylindrical parts

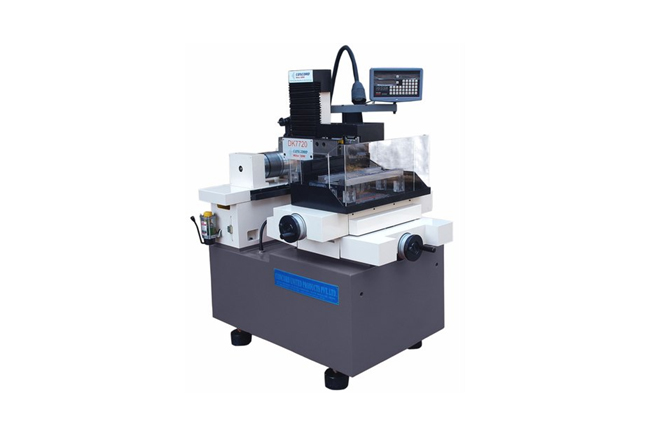

High – Precision cylindrical parts EDM Wire Cut

EDM Wire Cut EDM Spark

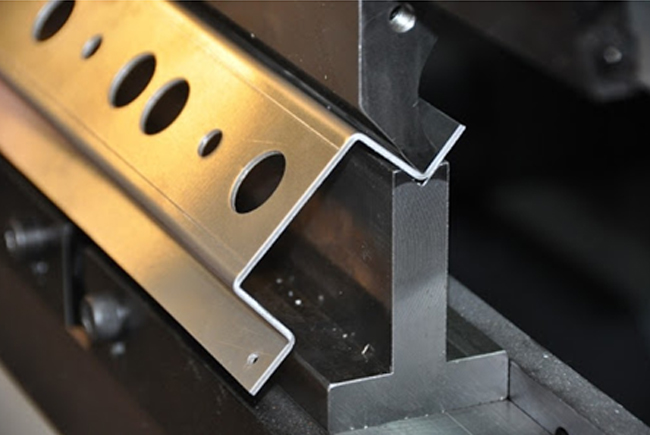

EDM Spark Bending Machine Sheet Metals

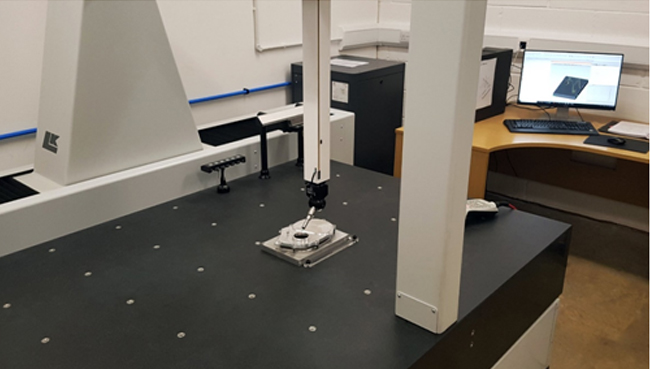

Bending Machine Sheet Metals CMM Inspection

CMM Inspection Pressfit

Pressfit Pressfit Top Dies

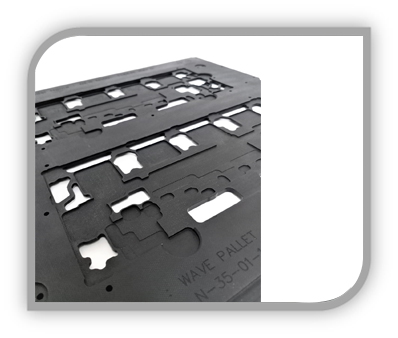

Pressfit Top Dies Wave Pallet

Wave Pallet Conformal Coating

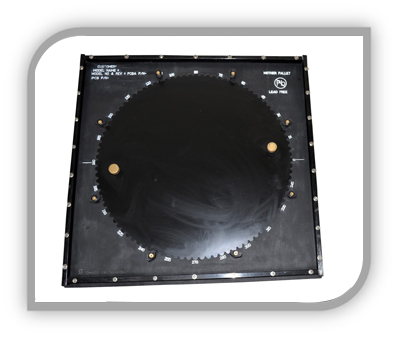

Conformal Coating Rotational Wave Pallet

Rotational Wave Pallet Titanium Wave Pallet

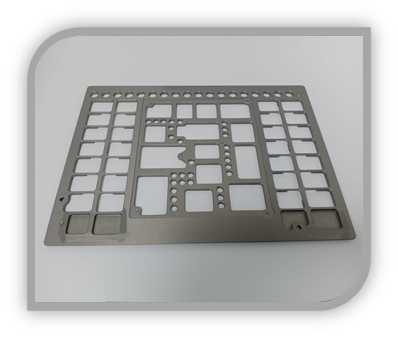

Titanium Wave Pallet Smt Pallet

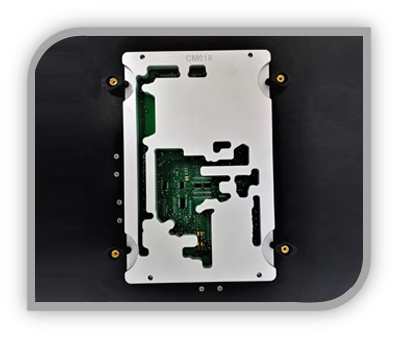

Smt Pallet Universal Carrier

Universal Carrier Custom assy Fixture

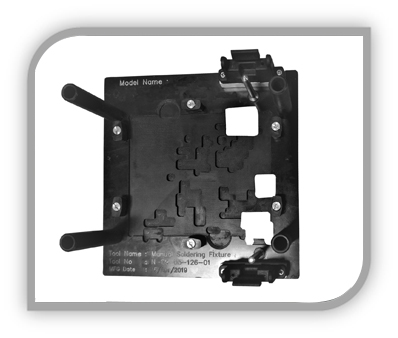

Custom assy Fixture Manual Soldering pallets

Manual Soldering pallets Selective Solder Pallets

Selective Solder Pallets