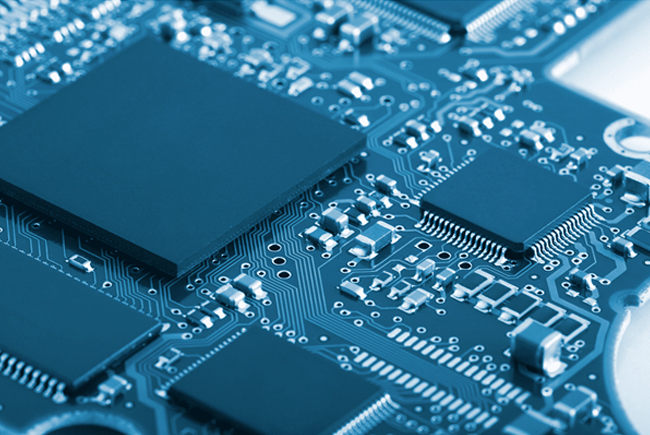

Semiconductor

In a bid to provide quicker solutions to the new customer challenges and to meet the hike in demand, Semiconductor OEMs, and EMSs, today, face the pressing need to take their products to market in the shortest time span, maintaining high levels of product quality while grappling with non-negotiable need of development & testing of SEMI standards-compliant products.

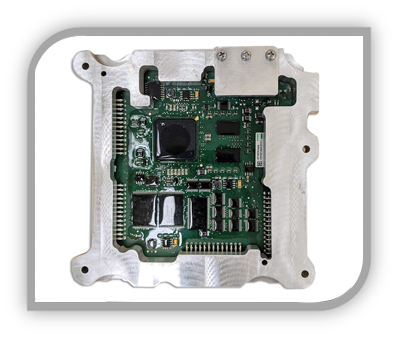

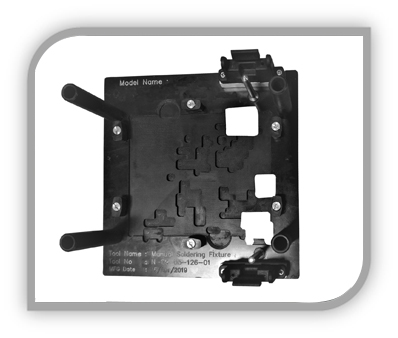

Smart Engineering provides integrated & comprehensive engineering solutions that are designed to semiconductor equipment OEMs and EMSs complex and ever-changing needs. We deliver impactful results with our capability in Soldering Fixture product development, creating enterprise solutions, enabling manufacturing and creating innovative digital solutions.

Semiconductor manufacturing Industry is the main Core business for Smart Engineering. Our machines are perfectly suited to the latest designs found in advanced semiconductor

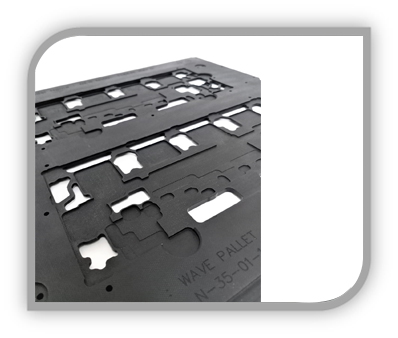

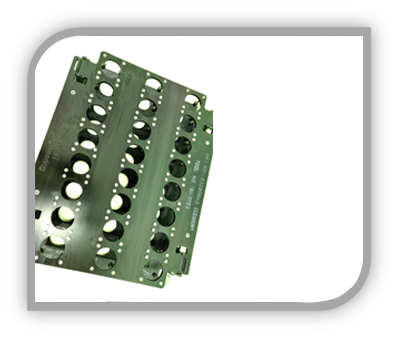

Wave soldering is a widely used technique in PCB assembly that involves soldering components onto the PCB using a wave of molten solder. However, the process can be challenging due to the need for precise positioning of the PCB and components to ensure proper soldering. This is where wave soldering pallets come in. In this article, we'll discuss the importance of wave soldering pallets and how Smart Engineering's offerings can help improve your wave soldering process.

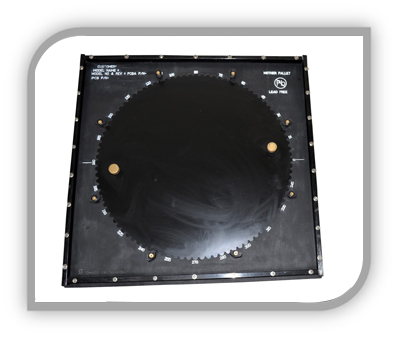

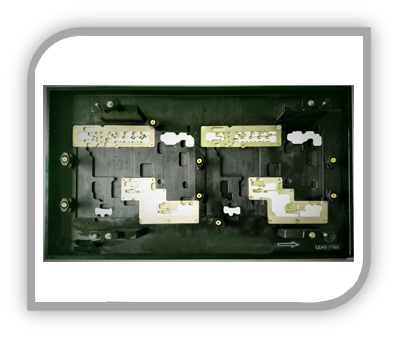

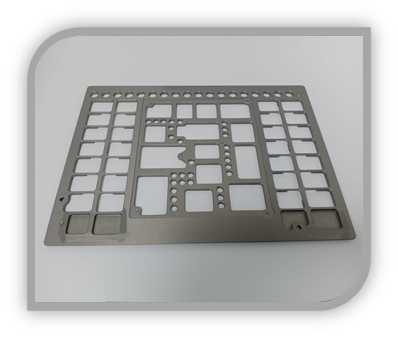

Wave soldering pallets are specialized fixtures designed to hold the PCB and components in place during the wave soldering process. They are designed to fit the dimensions and layout of the PCB being soldered, ensuring that the soldering process is accurate and consistent. The pallets are made from materials that can withstand the heat and stress of the wave soldering process and are designed to be easily cleaned and reused.

Smart Engineering offers a range of wave soldering pallets designed to meet the needs of a variety of applications. Their offerings include custom pallets, standard pallets, and adjustable pallets. These pallets are made from high-quality materials, such as fiberglass and epoxy, which can withstand the high temperatures and harsh chemicals used in the wave soldering process.

Custom pallets are designed to fit the dimensions and layout of the PCB being soldered, ensuring accurate and consistent soldering. Standard pallets are pre-designed to fit commonly used PCB sizes, while adjustable pallets can be adjusted to fit a range of PCB sizes. This customization ensures that the pallets fit the dimensions and layout of the PCB precisely, which helps to ensure accurate and reliable soldering.

Smart Engineering's wave soldering pallets are also designed to improve the efficiency of the wave soldering process. The pallets can be used to hold multiple PCBs and components at once, allowing for faster and more efficient soldering. They also reduce the need for manual handling of the PCB and components during the soldering process, which can help to reduce the risk of damage or errors.

In addition to their wave soldering pallets, Smart Engineering also offers a range of other PCB assembly solutions, including PCB testing fixtures, conformal coating fixtures, and router fixtures. Their focus on quality, customization, and customer service makes them a trusted partner for manufacturers looking to optimize their manufacturing processes.

Wave soldering pallets are essential tools for any manufacturer using the wave soldering process to manufacture electronic products. Smart Engineering's pallets offer a range of benefits, including improved accuracy, consistency, and efficiency, which can help to optimize the wave soldering process and improve the overall quality of the finished product. If you are looking to optimize your wave soldering process, consider working with Smart Engineering to develop a customized solution that meets your specific needs.

processing equipments. We pride ourselves in our ability to deliver on complex machining projects, with extremely high quality products. The key to the success of SME is the precision machining of High Quality products which are handled by skilled operators we have in our production group. They are capable of programming, setting up, running and evaluating the quality of the products they produce. Contact Smart Engineering today if you need complex work completed on a short schedule.

Semiconductor

Semiconductor Aviation

Aviation Medical

Medical Automobile

Automobile Special Purpose Machines

Special Purpose Machines 3 Axis Machining

3 Axis Machining 5 Axis Machining

5 Axis Machining Conventional Lathe with DRO

Conventional Lathe with DRO CNC Lathe Machining

CNC Lathe Machining High – Precision cylindrical parts

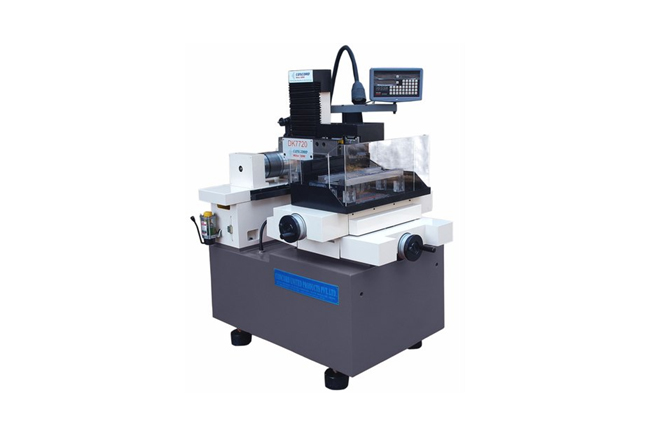

High – Precision cylindrical parts EDM Wire Cut

EDM Wire Cut EDM Spark

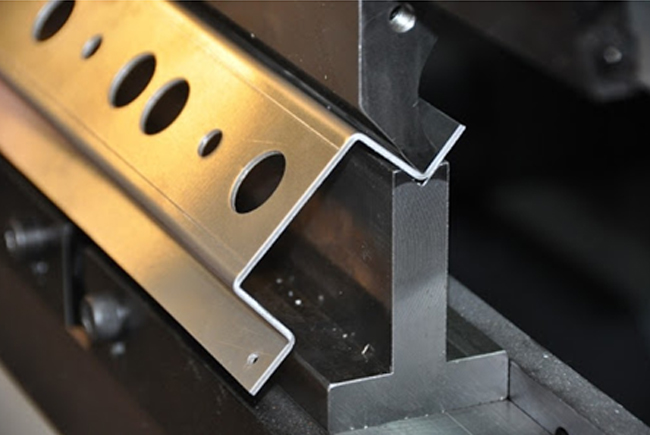

EDM Spark Bending Machine Sheet Metals

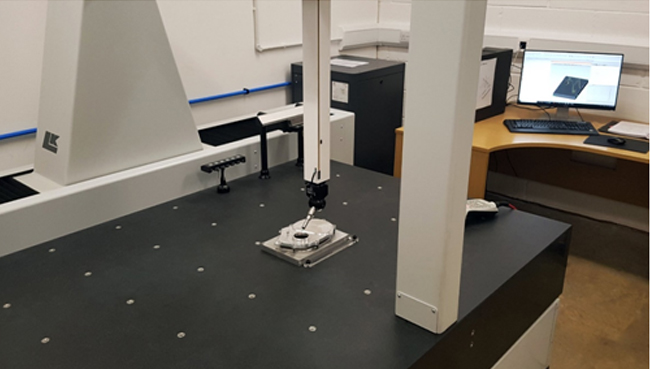

Bending Machine Sheet Metals CMM Inspection

CMM Inspection Pressfit

Pressfit Pressfit Top Dies

Pressfit Top Dies Wave Pallet

Wave Pallet Conformal Coating

Conformal Coating Rotational Wave Pallet

Rotational Wave Pallet Titanium Wave Pallet

Titanium Wave Pallet Smt Pallet

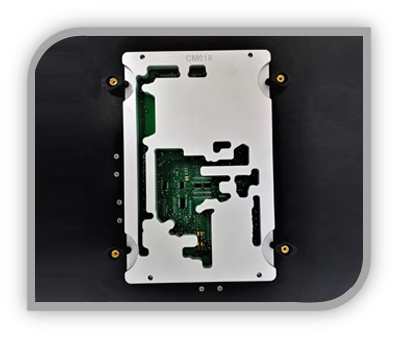

Smt Pallet Universal Carrier

Universal Carrier Custom assy Fixture

Custom assy Fixture Manual Soldering pallets

Manual Soldering pallets Selective Solder Pallets

Selective Solder Pallets