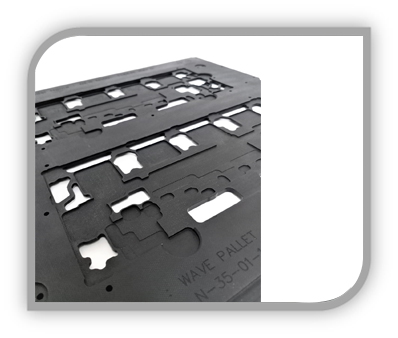

Wave soldering is a process used in the manufacturing of printed circuit boards (PCBs). The process involves passing the PCB over a wave of molten solder in order to solder the components onto the board. To ensure consistent and efficient soldering, wave soldering pallets are often used. In this article, we will discuss the benefits of using wave soldering pallets, and how Smart Engineer's pallets can help optimize your wave soldering process.

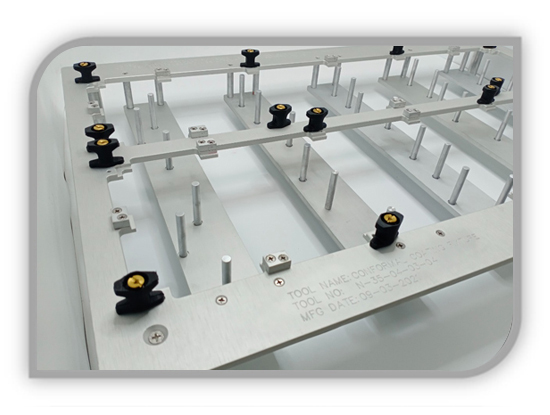

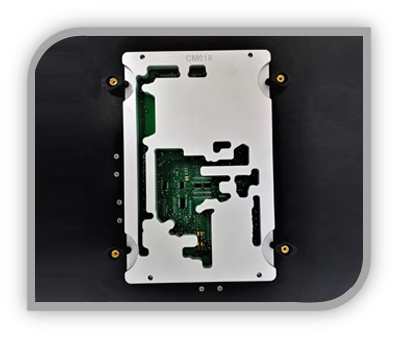

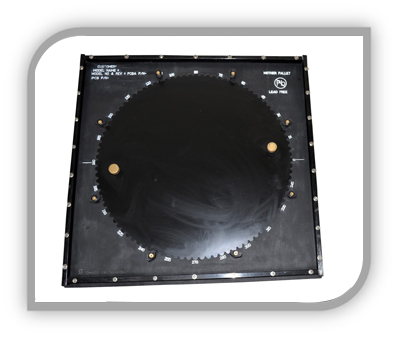

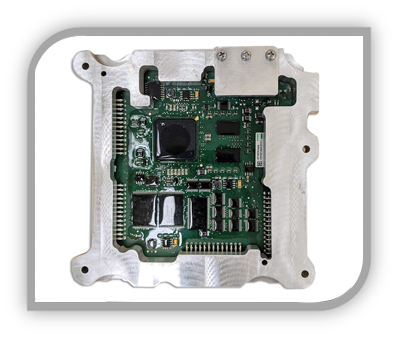

Wave soldering pallets are designed to hold the PCB securely in place during the wave soldering process. They are made from materials that can withstand the high temperatures and fluxes used during the soldering process, and are designed to be easily cleaned and reused. Pallets can be customized to fit the specific dimensions and layout of the PCB being manufactured, which ensures that the components are held in place securely and that the solder is applied precisely.

One of the main benefits of using wave soldering pallets is that they improve the consistency of the soldering process. By holding the PCB securely in place, the pallets prevent components from shifting or moving during the soldering process. This ensures that the solder is applied precisely and consistently, which helps to avoid defects such as solder bridges or cold solder joints. Consistent soldering also helps to improve the overall quality and reliability of the PCB.

Smart Engineering offers a range of wave soldering pallets that are designed to meet the needs of a variety of manufacturing applications. Their pallets are made from high-quality materials that can withstand the high temperatures and fluxes used during the wave soldering process. They are also designed to be easily cleaned and reused, which helps to reduce waste and manufacturing costs.

Smart Engineering's wave soldering pallets are customizable, which allows them to be tailored to the specific needs of each PCB being manufactured. This customization ensures that the pallets fit the dimensions and layout of the PCB precisely, which helps to ensure that the components are held securely in place during the soldering process. This results in more consistent soldering, which helps to improve the overall quality and reliability of the PCB.

In addition to their wave soldering pallets, Smart Engineering also offers a range of other PCB manufacturing solutions, including reflow soldering pallets, SMT fixtures, and more. Their focus on quality, customization, and customer service makes them a trusted partner for manufacturers looking to optimize their PCB manufacturing processes.

Wave soldering pallets are an essential tool for any manufacturer using the wave soldering process to manufacture PCBs. Smart Engineering's wave soldering pallets offer a range of benefits, including improved consistency, reliability, and customization, which can help to optimize the wave soldering process and improve the overall quality of the PCB. If you are looking to optimize your wave soldering process, consider working with Smart Engineer to develop a customized solution that meets your specific needs.

PCB assembly is a complex process that involves assembling electronic components onto a printed circuit board (PCB). To ensure that this process is efficient and precise, PCB assembly tooling jigs and fixtures are often used. In this article, we will discuss the benefits of using tooling jigs and fixtures in PCB assembly, and how Smart Engineer's offerings can help improve your PCB assembly process.

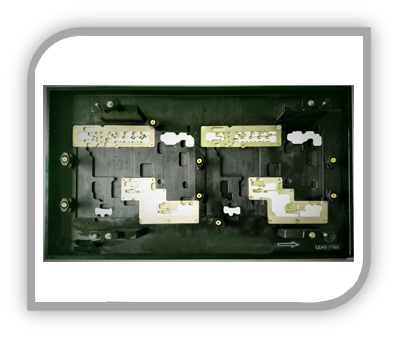

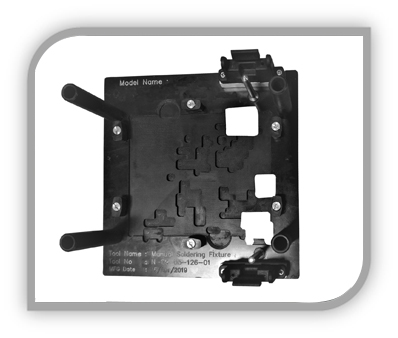

Tooling jigs and fixtures are designed to hold the PCB and components in place during the assembly process. They are made from materials that can withstand the high temperatures and stresses of the assembly process, and are designed to be easily cleaned and reused. Jigs and fixtures can be customized to fit the specific dimensions and layout of the PCB being assembled, which ensures that the components are held in place securely and that the assembly process is efficient and precise.

One of the main benefits of using tooling jigs and fixtures in PCB assembly is that they improve the accuracy and consistency of the assembly process. By holding the PCB and components in place, the jigs and fixtures prevent shifting or movement during the assembly process. This ensures that the components are assembled precisely and consistently, which helps to avoid defects and improve the overall quality and reliability of the finished product.

Smart Engineering offers a range of tooling jigs and fixtures that are designed to meet the needs of a variety of PCB assembly applications. Their offerings include SMT fixtures, wave soldering pallets, selective soldering fixtures, and more. These jigs and fixtures are made from high-quality materials that can withstand the stresses of the assembly process and are designed to be easily cleaned and reused.

Smart Engineering's tooling jigs and fixtures are customizable, which allows them to be tailored to the specific needs of each PCB being assembled. This customization ensures that the jigs and fixtures fit the dimensions and layout of the PCB precisely, which helps to ensure that the components are held securely in place during the assembly process. This results in more accurate and consistent assembly, which helps to improve the overall quality and reliability of the finished product.

In addition to their tooling jigs and fixtures, Smart Engineering also offers a range of other PCB assembly solutions, including reflow ovens, solder paste dispensers, and more. Their focus on quality, customization, and customer service makes them a trusted partner for manufacturers looking to optimize their PCB assembly processes.

PCBs are critical components of modern electronics, and it's essential that they function correctly. PCB testing fixtures are an essential tool for manufacturers, enabling them to test their PCBs for functionality, performance, and quality. In this article, we'll discuss the importance of PCB testing fixtures and how Smart Engineering's offerings can help improve your PCB testing process.

PCB testing fixtures are designed to test PCBs for electrical continuity, functionality, and performance. They are used to test PCBs for defects, such as shorts, open circuits, or incorrect connections. By using PCB testing fixtures, manufacturers can ensure that their products meet the required quality standards and perform reliably.

Smart Engineering offers a range of PCB testing fixtures designed to meet the needs of a variety of applications. Their offerings include flying probe fixtures, bed-of-nails fixtures, and functional test fixtures. These fixtures are designed to test PCBs for a wide range of parameters, including electrical continuity, performance, and functionality.

Flying probe fixtures are designed to test PCBs for electrical continuity and functionality. These fixtures use a set of probes to test the PCB without the need for dedicated test points. Bed-of-nails fixtures are designed to test PCBs for electrical continuity and are typically used for high-volume production runs. Functional test fixtures are designed to test PCBs for specific functions or parameters, such as power consumption or signal integrity.

Smart Engineering's PCB testing fixtures are customizable, allowing them to be tailored to the specific needs of each PCB being tested. This customization ensures that the fixtures fit the dimensions and layout of the PCB precisely, which helps to ensure accurate and reliable testing.

In addition to their PCB testing fixtures, Smart Engineering also offers a range of other PCB testing solutions, including in-circuit testing and automated optical inspection. Their focus on quality, customization, and customer service makes them a trusted partner for manufacturers looking to optimize their PCB testing processes.

In conclusion, PCB testing fixtures are an essential tool for any manufacturer using the PCB assembly process to manufacture electronic products. Smart Engineering's PCB testing fixtures offer a range of benefits, including improved accuracy, reliability, and customization, which can help to optimize the PCB testing process and improve the overall quality of the finished product. If you are looking to optimize your PCB testing process, consider working with Smart Engineering to develop a customized solution that meets your specific needs.

Conformal coatings are used to protect printed circuit boards (PCBs) and electronic components from environmental factors, such as moisture, dust, and chemicals. Applying conformal coatings accurately and consistently can be a challenging task, which is why conformal coating fixtures are essential. In this article, we'll discuss the importance of conformal coating fixtures and how Smart Engineering's offerings can help improve your conformal coating process.

Conformal coating fixtures are designed to hold PCBs and electronic components in place during the conformal coating process. They are designed to fit the dimensions and layout of the PCBs and components being coated, ensuring accurate and consistent application of the conformal coating material.

Smart Engineering offers a range of conformal coating fixtures designed to meet the needs of a variety of applications. Their offerings include custom fixtures, spray coating fixtures, and dip coating fixtures. These fixtures are made from high-quality materials that can withstand the stresses of the conformal coating process and are designed to be easily cleaned and reused.

Custom fixtures are designed to fit the dimensions and layout of the PCB and components being coated, ensuring accurate and consistent application of the conformal coating material. Spray coating fixtures are designed to hold the PCB and components in place while the conformal coating material is sprayed onto the surface. Dip coating fixtures are designed to hold the PCB and components in place while they are dipped into the conformal coating material.

Smart Engineering's conformal coating fixtures are customizable, allowing them to be tailored to the specific needs of each PCB being coated. This customization ensures that the fixtures fit the dimensions and layout of the PCB and components precisely, which helps to ensure accurate and reliable application of the conformal coating material.

In addition to their conformal coating fixtures, Smart Engineering also offers a range of other conformal coating solutions, including spray coating equipment and dip coating equipment. Their focus on quality, customization, and customer service makes them a trusted partner for manufacturers looking to optimize their conformal coating processes.

In conclusion, conformal coating fixtures are an essential tool for any manufacturer using the PCB assembly process to manufacture electronic products. Smart Engineering's conformal coating fixtures offer a range of benefits, including improved accuracy, consistency, and customization, which can help to optimize the conformal coating process and improve the overall quality of the finished product. If you are looking to optimize your conformal coating process, consider working with Smart Engineering to develop a customized solution that meets your specific needs.

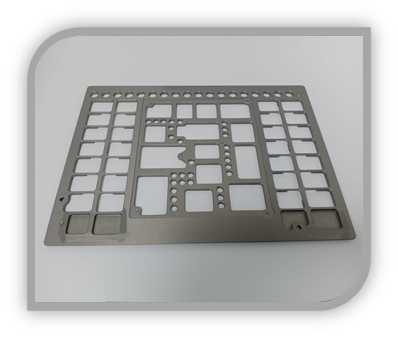

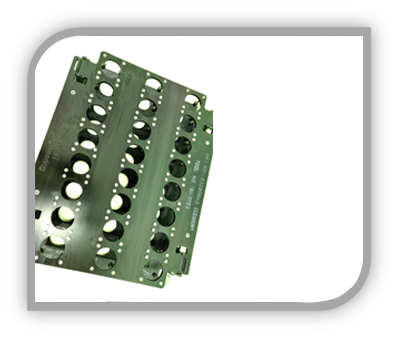

Router fixtures are an essential tool for any manufacturer using the printed circuit board (PCB) assembly process. They are used to hold the PCB in place during the routing process, ensuring that the PCB is cut accurately and consistently. In this article, we'll discuss the importance of router fixtures and how Smart Engineering's offerings can help improve your routing process.

Router fixtures are designed to hold the PCB securely in place during the routing process, preventing movement or vibration that can cause errors in the routing process. They are designed to fit the dimensions and layout of the PCB being routed, ensuring that the routing process is accurate and consistent. Smart Engineering offers a range of router fixtures designed to meet the needs of a variety of applications. Their offerings include custom fixtures, vacuum fixtures, and manual fixtures. These fixtures are made from high-quality materials that can withstand the stresses of the routing process and are designed to be easily cleaned and reused. Custom fixtures are designed to fit the dimensions and layout of the PCB being routed, ensuring accurate and consistent routing. Vacuum fixtures use suction to hold the PCB securely in place during the routing process, while manual fixtures use clamps or other holding mechanisms to hold the PCB in place. Smart Engineering's router fixtures are customizable, allowing them to be tailored to the specific needs of each PCB being routed. This customization ensures that the fixtures fit the dimensions and layout of the PCB precisely, which helps to ensure accurate and reliable routing. In addition to their router fixtures, Smart Engineering also offers a range of other PCB routing solutions, including CNC routers and manual routers. Their focus on quality, customization, and customer service makes them a trusted partner for manufacturers looking to optimize their routing processes. In conclusion, router fixtures are an essential tool for any manufacturer using the PCB assembly process to manufacture electronic products. Smart Engineering's router fixtures offer a range of benefits, including improved accuracy, consistency, and customization, which can help to optimize the routing process and improve the overall quality of the finished product. If you are looking to optimize your routing process, consider working with Smart Engineering to develop a customized solution that meets your specific needs.Creative Ideas

24/7 Support

Smart Engineering provides the best service for sustainable progress.

Get in touch

You will find yourself working in a true partnership that results in an incredible experience, and an end product that is the best.

Call us on

+91 90801 89286

+91 87781 22517

Semiconductor

Semiconductor Aviation

Aviation Medical

Medical Automobile

Automobile Special Purpose Machines

Special Purpose Machines 3 Axis Machining

3 Axis Machining 5 Axis Machining

5 Axis Machining Conventional Lathe with DRO

Conventional Lathe with DRO CNC Lathe Machining

CNC Lathe Machining High – Precision cylindrical parts

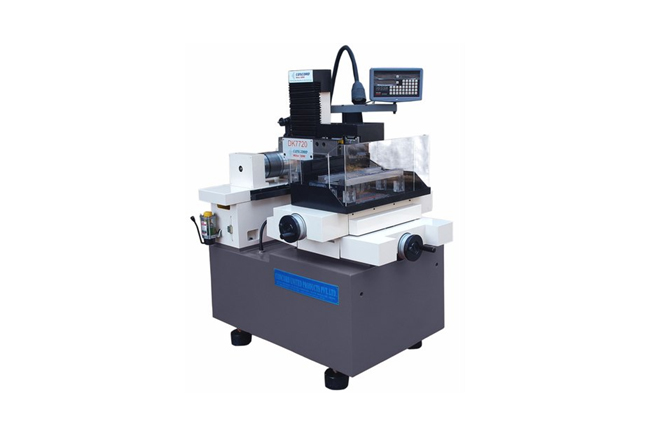

High – Precision cylindrical parts EDM Wire Cut

EDM Wire Cut EDM Spark

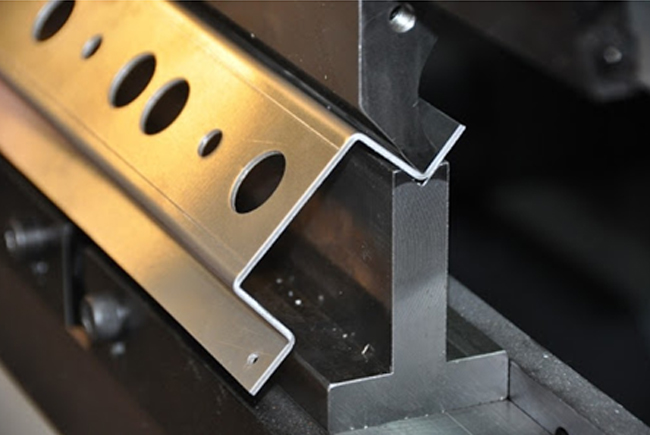

EDM Spark Bending Machine Sheet Metals

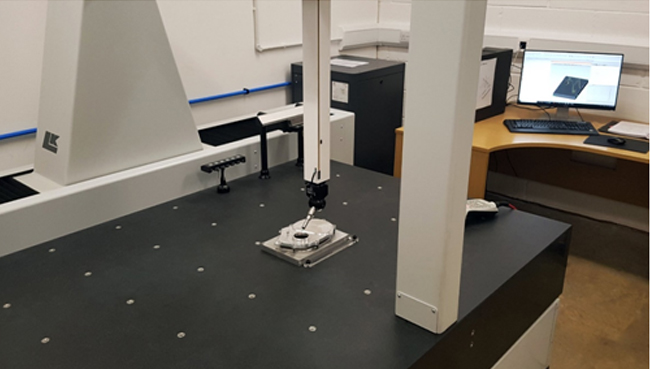

Bending Machine Sheet Metals CMM Inspection

CMM Inspection Pressfit

Pressfit Pressfit Top Dies

Pressfit Top Dies Wave Pallet

Wave Pallet Conformal Coating

Conformal Coating Rotational Wave Pallet

Rotational Wave Pallet Titanium Wave Pallet

Titanium Wave Pallet Smt Pallet

Smt Pallet Universal Carrier

Universal Carrier Custom assy Fixture

Custom assy Fixture Manual Soldering pallets

Manual Soldering pallets Selective Solder Pallets

Selective Solder Pallets