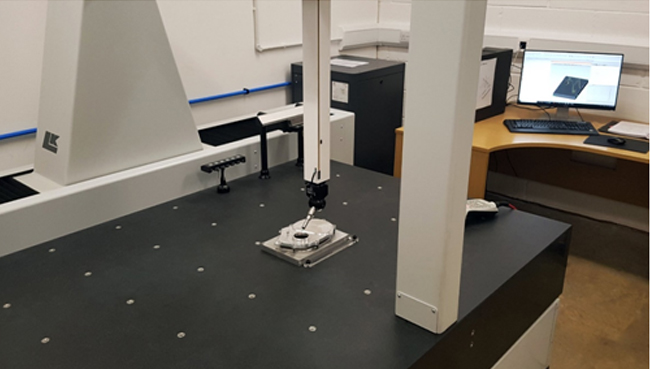

CMM Inspection

A coordinate measuring machine (CMM) is a device that measures the geometry of physical objects by sensing discrete points on the surface of the object with a probe. Various types of probes are used in CMMs, including mechanical, optical, laser, and white light. Depending on the machine, the probe position may be manually controlled by an operator or it may be computer controlled. CMMs typically specify a probe's position in terms of its displacement from a reference position in a three-dimensional Cartesian coordinate system (i.e., with XYZ axes). In addition to moving the probe along the X, Y, and Z axes, many machines also allow the probe angle to be controlled to allow measurement of surfaces that would otherwise be unreachable.

We at smart engineering provide on customer demand, to supply the products with CMM report. We suggested to get a “NABL” Certified centres to get a report along with products. If 5-Axis on all products are certified only.

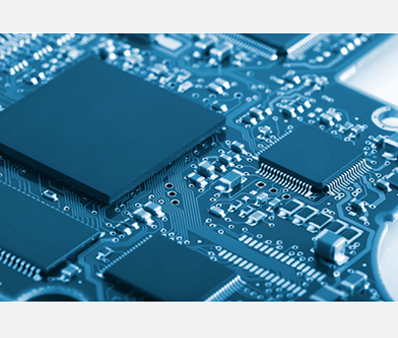

Semiconductor

Semiconductor Aviation

Aviation Medical

Medical Automobile

Automobile Special Purpose Machines

Special Purpose Machines 3 Axis Machining

3 Axis Machining 5 Axis Machining

5 Axis Machining Conventional Lathe with DRO

Conventional Lathe with DRO CNC Lathe Machining

CNC Lathe Machining High – Precision cylindrical parts

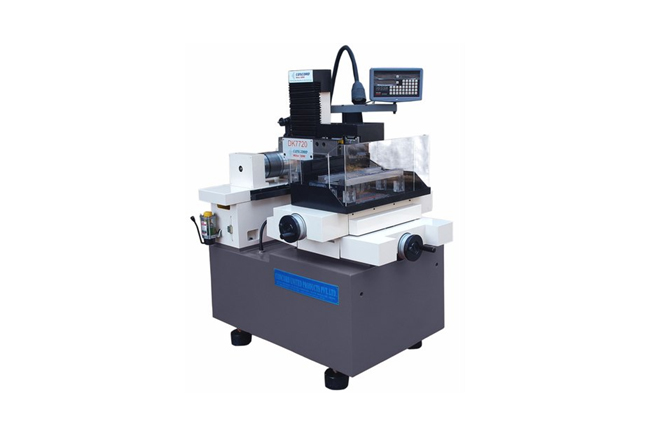

High – Precision cylindrical parts EDM Wire Cut

EDM Wire Cut EDM Spark

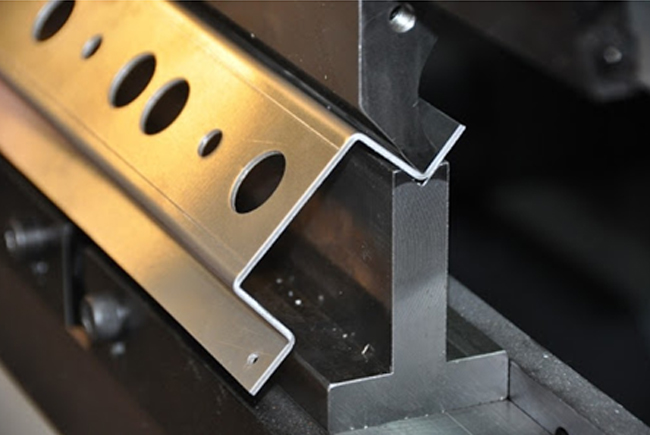

EDM Spark Bending Machine Sheet Metals

Bending Machine Sheet Metals Pressfit

Pressfit Pressfit Top Dies

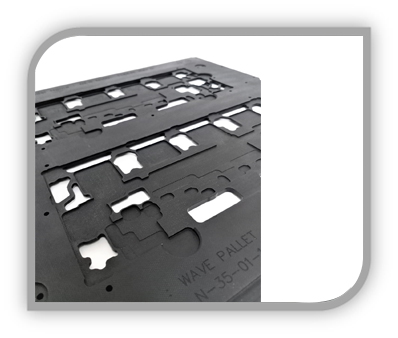

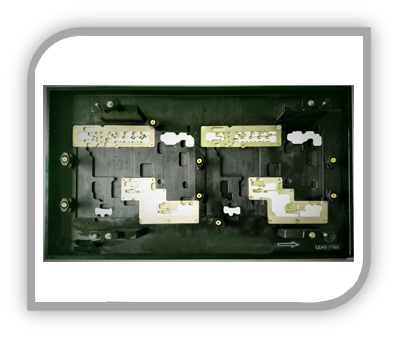

Pressfit Top Dies Wave Pallet

Wave Pallet Conformal Coating

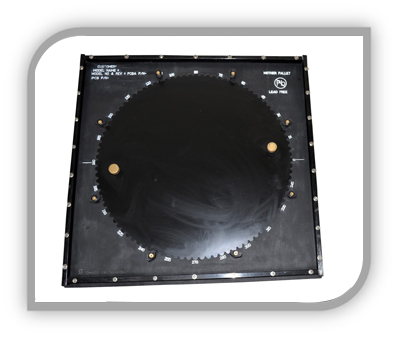

Conformal Coating Rotational Wave Pallet

Rotational Wave Pallet Titanium Wave Pallet

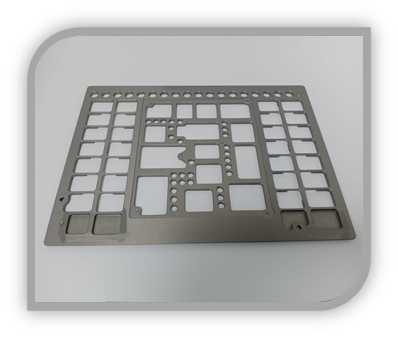

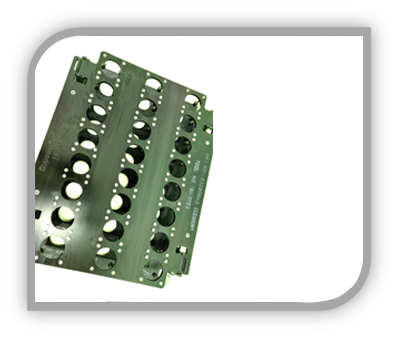

Titanium Wave Pallet Smt Pallet

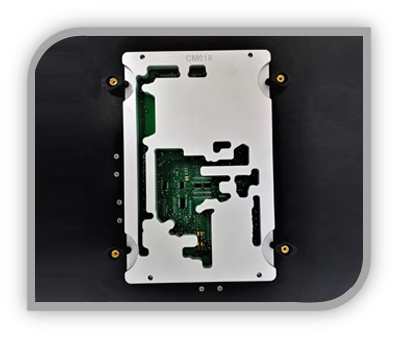

Smt Pallet Universal Carrier

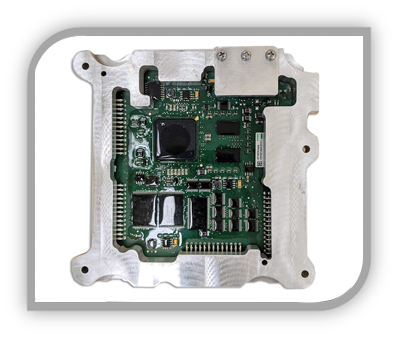

Universal Carrier Custom assy Fixture

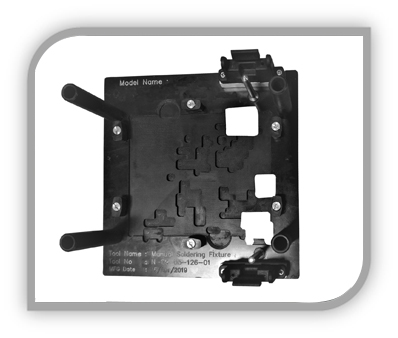

Custom assy Fixture Manual Soldering pallets

Manual Soldering pallets Selective Solder Pallets

Selective Solder Pallets