Medical

The Medical Device Industry Is More Competitive Than Ever Due To A Crowded, Global Marketplace, Stringent Regulatory Requirements And Increased Pressure To Grow The Bottom Line. Medical Device Manufacturers Leading The Industry Are Turning To Integrated, Seamless Platforms To Support All Phases Of The Lifecycle, Including Integrated Manufacturing.

Our Part Manufacturing Solutions Provide A Unified And Open Design-Through-Manufacturing Process Using A Virtual Model, A Digital Twin That Perfectly Represents The Physical Device, To Enhance Efficiency On The Shop Floor.

With Our Integrated Model-Driven Processes, Starting With Cad/Cam/Cae Of Parts, And Running Though To Automated Production And Quality Control, We Are Delivering A New Era Of Part Manufacturing Productivity.

Our Best-In-Class Technology For Medical Device Manufacturers Supports Traditional Manufacturing Processes Such As Cnc Machining And Injection Molding, As Well As New Revolutionary Technologies Such As Additive Manufacturing And Robotic Machining. By Embracing Digitalization, Your Organization Can Maximize Profitability With Flawless Product Design And Manufacturing Processes From Start To Finish. Contact Smart Engineering we will contribute to your success with our excellent engineering and Manufacturing teams.

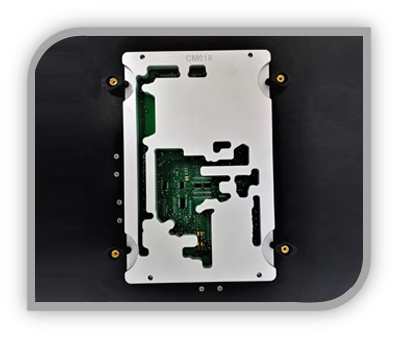

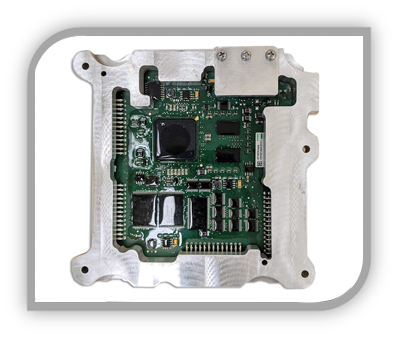

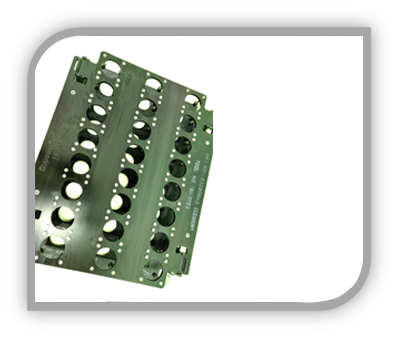

PCB testing is an essential step in the manufacturing process to ensure that the finished product functions correctly. PCB testing fixtures are specialized devices that provide a stable and secure platform for testing PCBs. In this article, we'll discuss the importance of PCB testing fixtures and how Smart Engineering's offerings can help improve your testing process.

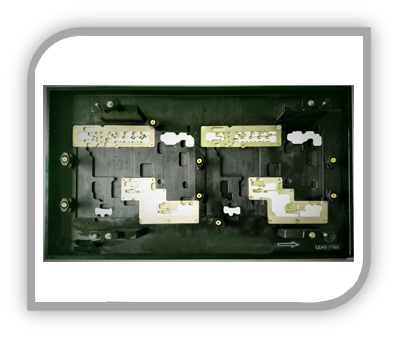

PCB testing fixtures are designed to hold PCBs in place during the testing process. They provide a stable and secure platform for the PCB, ensuring accurate and consistent testing results. The fixtures can also be customized to fit the dimensions and layout of the PCB being tested, ensuring that the PCB is held securely in place during testing.

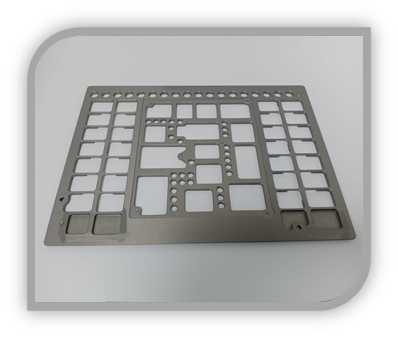

Smart Engineering offers a range of PCB testing fixtures that are designed to meet the needs of a variety of applications. Their offerings include custom fixtures, standard fixtures, and adjustable fixtures. These fixtures are made from high-quality materials, such as aluminum and steel, which provide durability and strength for the testing process.

Custom fixtures are designed to fit the dimensions and layout of the PCB being tested, ensuring accurate and consistent testing results. Standard fixtures are pre-designed to fit commonly used PCB sizes, while adjustable fixtures can be adjusted to fit a range of PCB sizes. This customization ensures that the fixtures fit the dimensions and layout of the PCB precisely, which helps to ensure accurate and reliable testing results.

Smart Engineering's PCB testing fixtures are also designed to improve the efficiency of the testing process. The fixtures can be used to hold multiple PCBs at once, allowing for faster and more efficient testing. They also reduce the need for manual handling of the PCBs during the testing process, which can help to reduce the risk of damage or errors.

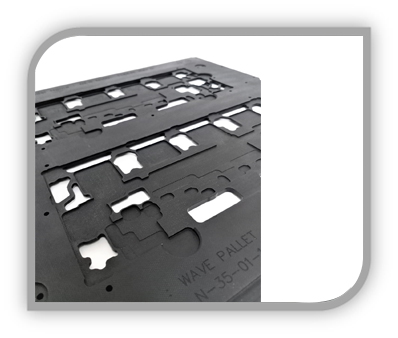

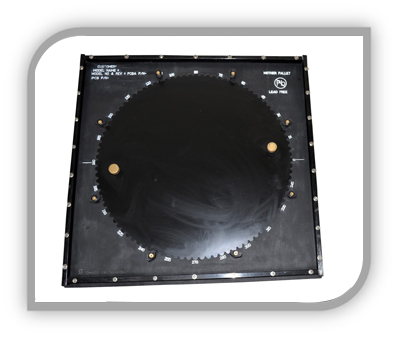

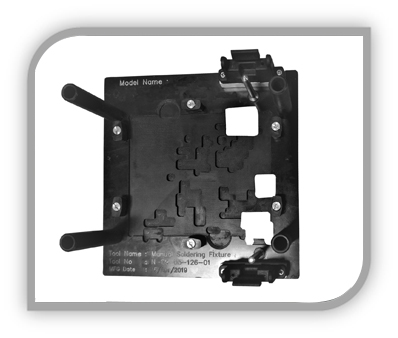

In addition to their testing fixtures, Smart Engineering also offers a range of other PCB assembly solutions, including tooling jigs and fixtures, wave soldering pallets, conformal coating fixtures, and router fixtures. Their focus on quality, customization, and customer service makes them a trusted partner for manufacturers looking to optimize their manufacturing processes.

PCB testing fixtures are essential components of any PCB testing process. Smart Engineering's fixtures offer a range of benefits, including improved accuracy, consistency, and efficiency, which can help to optimize the testing process and improve the overall quality of the finished product. If you are looking to optimize your PCB testing process, consider working with Smart Engineering to develop a customized solution that meets your specific needs.

Semiconductor

Semiconductor Aviation

Aviation Medical

Medical Automobile

Automobile Special Purpose Machines

Special Purpose Machines 3 Axis Machining

3 Axis Machining 5 Axis Machining

5 Axis Machining Conventional Lathe with DRO

Conventional Lathe with DRO CNC Lathe Machining

CNC Lathe Machining High – Precision cylindrical parts

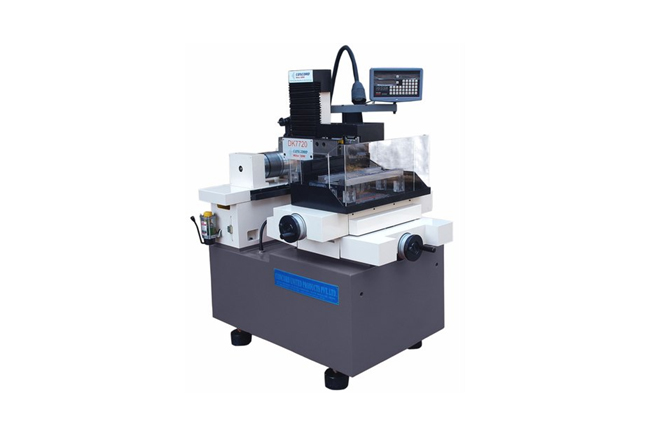

High – Precision cylindrical parts EDM Wire Cut

EDM Wire Cut EDM Spark

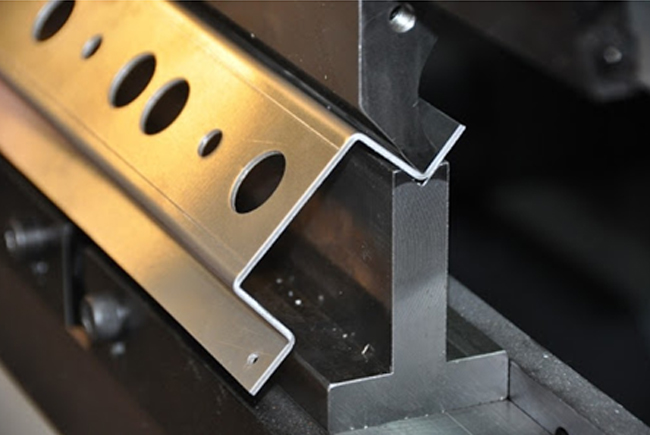

EDM Spark Bending Machine Sheet Metals

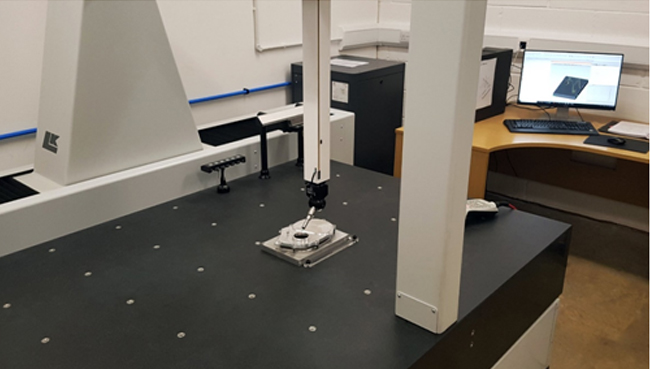

Bending Machine Sheet Metals CMM Inspection

CMM Inspection Pressfit

Pressfit Pressfit Top Dies

Pressfit Top Dies Wave Pallet

Wave Pallet Conformal Coating

Conformal Coating Rotational Wave Pallet

Rotational Wave Pallet Titanium Wave Pallet

Titanium Wave Pallet Smt Pallet

Smt Pallet Universal Carrier

Universal Carrier Custom assy Fixture

Custom assy Fixture Manual Soldering pallets

Manual Soldering pallets Selective Solder Pallets

Selective Solder Pallets