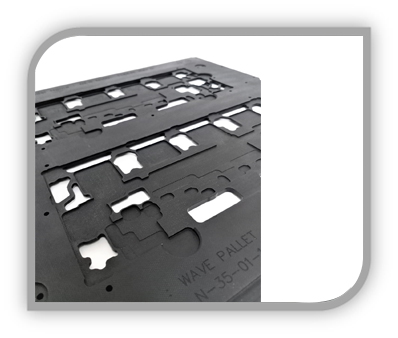

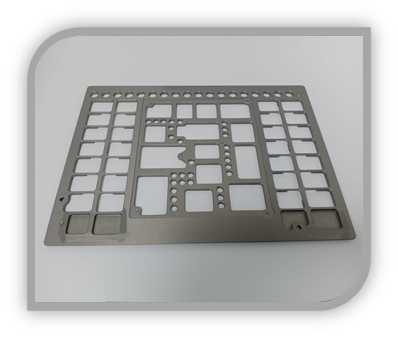

Wave Solder Pallets

Key Elements of a Wave Solder Pallet:

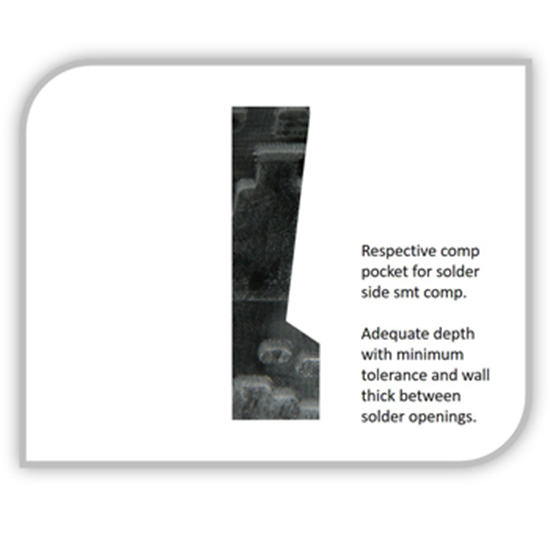

- Wave Solder Pallets are used to mask ground planes, gold fingers, Hardware holes , Non mounting holes, and SMT components while exposing the PCB to the wave only where, the solder is required.

- Eliminates hand gluing of SMT parts and masking of through-hole parts,Decreases the labor Cost by avoiding manual touchups , Eliminates the defects, Reduce reworks and eliminating the cost of masking tape (polymide).

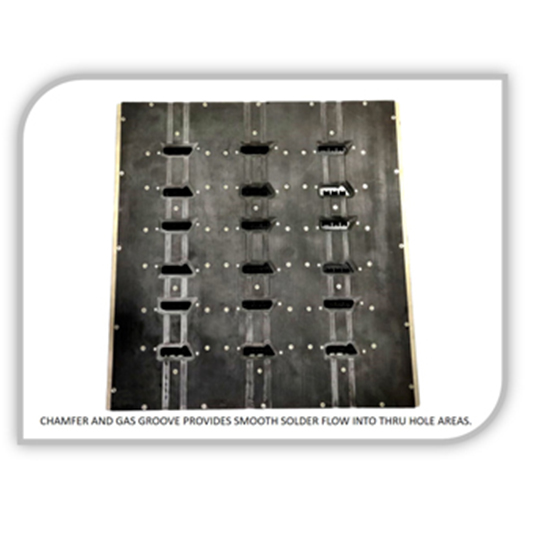

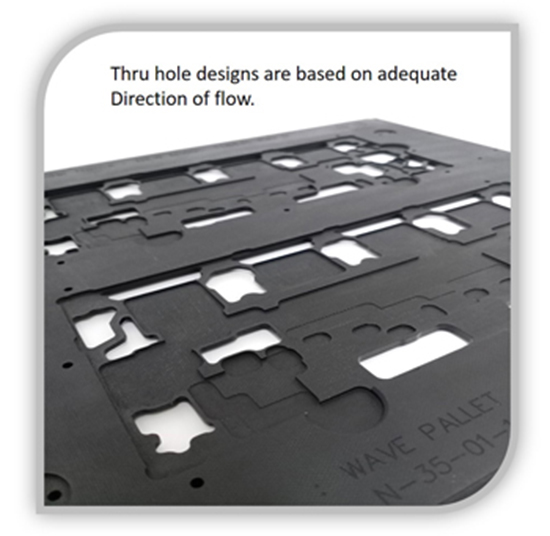

- Solder flow will be improved in through hole areas,

- Gas Grooves - Channels for hot gas to escape resulting in infrequent defects and also to minimize the blow hole effect to release surface tension. Act as solder convoy from in and out in through hole openings.

- Chamfer & Wave Pocket - Improves smoothness of solder in and out , Avoids shadow effect,Avoids Solder Joints & Bridging Effect.

- Stiffeners – Fiber Composites - solder will not come in contact with the surface.

- Holddowns are ergonomic, durable to hold the PCB securely in required places. Our Holdowns are designed to handle any PCB Height.

- Top Hat(ESD G-10) - To hold through-hole components in places and also it can be used as an alignment feature. (Lacthes with S.S Dowels and Brass Alingers).

- Edge Step – 2mm Thick Titanium -GR2 provides proper rigidity to the fixture and act as a solder dam to keep solder from flooding inside the PCB.

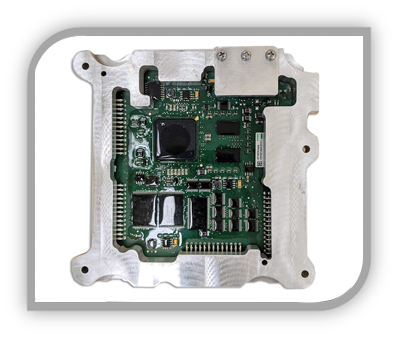

Semiconductor

Semiconductor Aviation

Aviation Medical

Medical Automobile

Automobile Special Purpose Machines

Special Purpose Machines 3 Axis Machining

3 Axis Machining 5 Axis Machining

5 Axis Machining Conventional Lathe with DRO

Conventional Lathe with DRO CNC Lathe Machining

CNC Lathe Machining High – Precision cylindrical parts

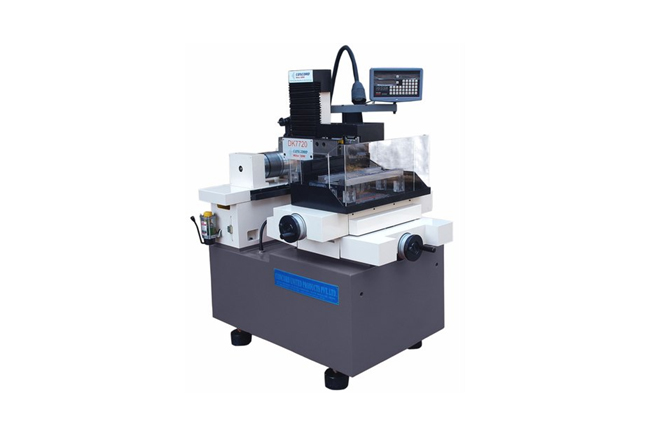

High – Precision cylindrical parts EDM Wire Cut

EDM Wire Cut EDM Spark

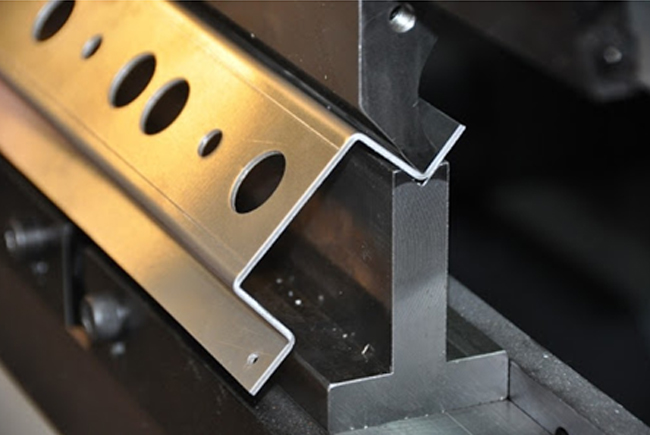

EDM Spark Bending Machine Sheet Metals

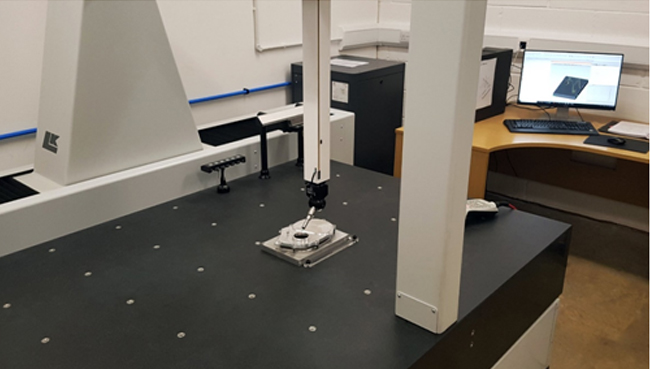

Bending Machine Sheet Metals CMM Inspection

CMM Inspection Pressfit

Pressfit Pressfit Top Dies

Pressfit Top Dies Wave Pallet

Wave Pallet Conformal Coating

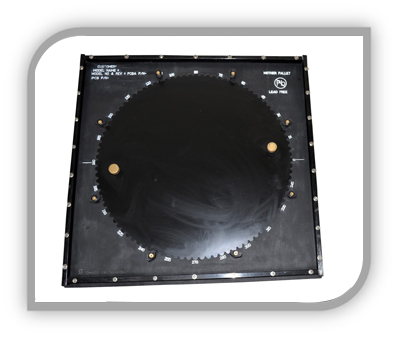

Conformal Coating Rotational Wave Pallet

Rotational Wave Pallet Titanium Wave Pallet

Titanium Wave Pallet Smt Pallet

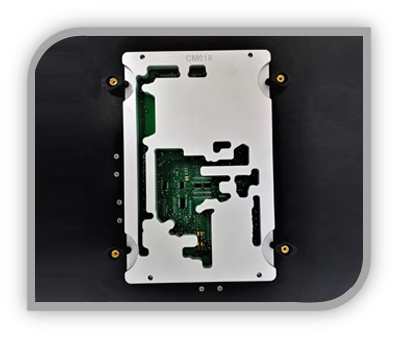

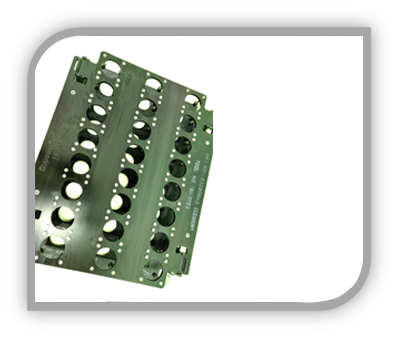

Smt Pallet Universal Carrier

Universal Carrier Custom assy Fixture

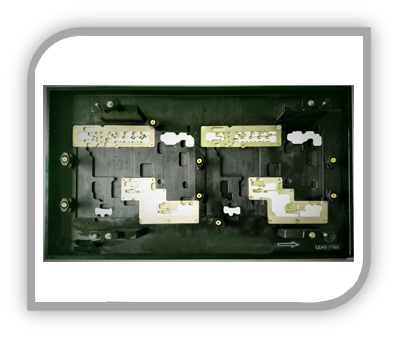

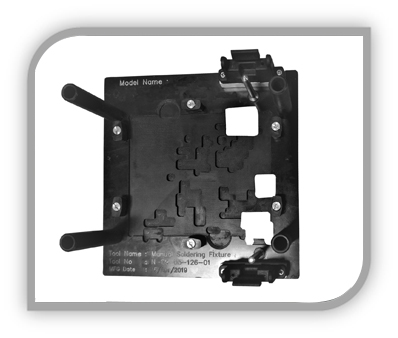

Custom assy Fixture Manual Soldering pallets

Manual Soldering pallets Selective Solder Pallets

Selective Solder Pallets